In the modern manufacturing industry, accuracy, speed, and efficiency are the keys to success. Traditional methods often fall short in meeting the growing demand for high-quality and cost-effective production. This is where CNC machining steps in as a game-changer. But what exactly is CNC machining, and why do so many businesses depend on it today?

What is CNC Machining?

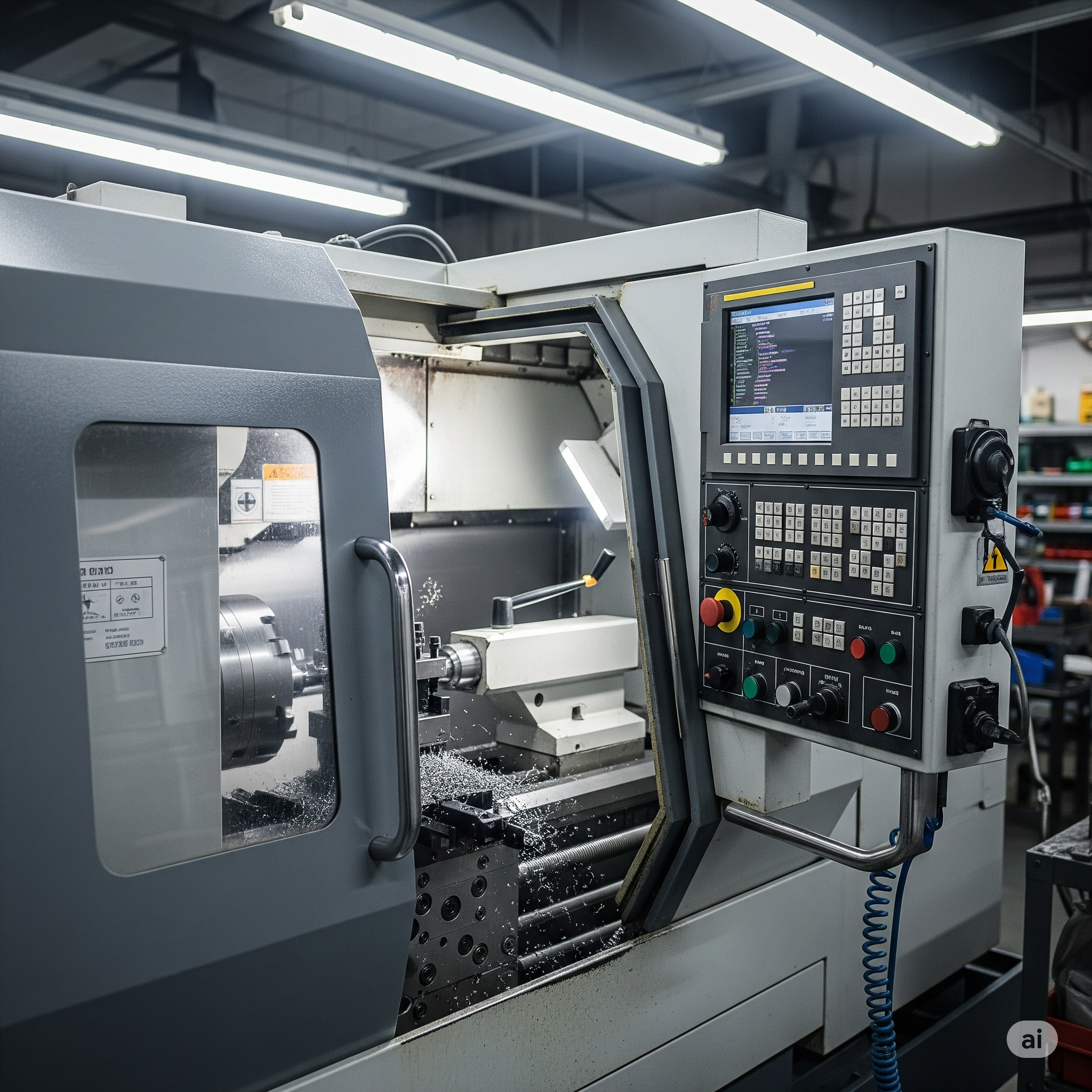

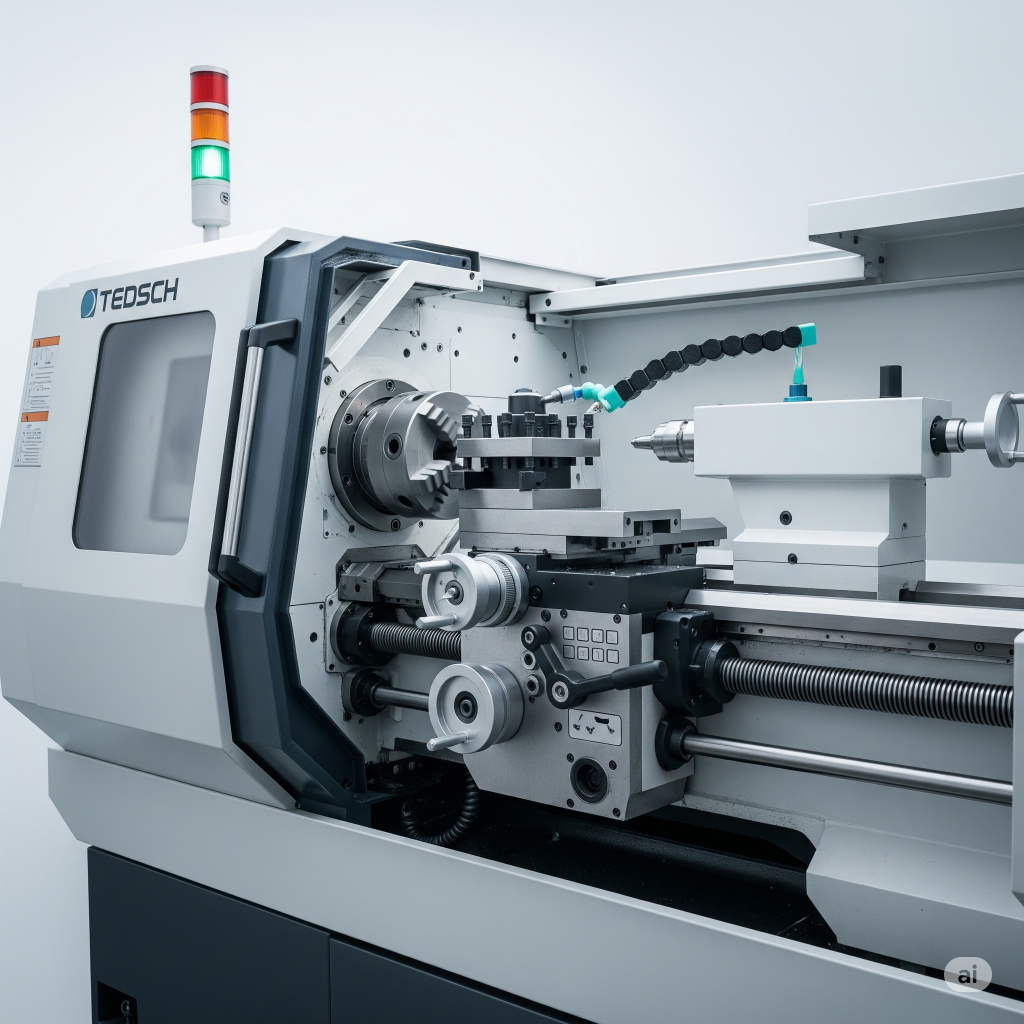

CNC (Computer Numerical Control) machining is a manufacturing process where computers control machine tools such as lathes, mills, grinders, and routers. Instead of operating machines manually, CNC uses a pre-programmed set of instructions to cut, shape, and create parts with extreme accuracy.

Think of it as a robotic craftsman – the design is created on CAD (Computer-Aided Design) software, converted into CNC codes, and the machine executes the commands flawlessly.

How CNC Machining Works?

- Design Creation – Engineers create a part design using CAD software.

- Programming – The design is converted into CNC instructions (G-code).

- Machine Setup – The right tools and materials are loaded into the machine.

- Execution – The CNC machine cuts, drills, or shapes the material automatically.

- Finishing – The final product is checked for quality and precision.

- This process ensures consistent results and reduces the chances of human error.